Steve Howlett

sculptor

Working a piece

This page of technical information was written specifically for my turned wood pieces but it is relevant to the bronzes too, as many of the original maquettes for the bronzes are created in this way from wood. Just click on the tabs above for more information.

I enjoy the visual ambiguity of my work. At first sight it appears to be made from materials other than wood, but in fact many of the forms could be made in no other medium. I am not interested in using dramatic pieces of wood for my work as, eventually, over centuries, all colour will either fade or darken, all grain patterns will disappear into insignificance. Ultimately, all that is left is the form.

The woods I use are mostly holly, sycamore, olive ash and some fruit woods, such as apple and cherry. My reason for choosing to work these woods in particular is due to their inherent, natural characteristics. Holly (Ilex aquifoleum) shrinks a great deal as it seasons (dries), giving me interesting and extreme distortions of form. Sycamore (Acer pseudoplatanus) does not shrink much thereby giving me less extreme distortion of form whilst often exhibiting subtle visual effects of the grain e.g. rippling or quilting; it is also available in large dimensions which allows me a greater freedom of design. Olive ash (Fraxinus excelsior) is used for similar reasons to sycamore, it also has the most unusual and exquisite patterning and figure. Approximately 90% of the timber I use is from wind blown trees or managed felling and almost all of it comes from within approximately 30 miles of my studio. I feel that using timber indigenous to the area in which I work gives a certain indefinable but unique character to the work.

The growing tree may contain up to 60% by weight of water. Once the timber is cut, this water is lost over time by evaporation (known as seasoning). This loss of moisture causes the wood to shrink and it is this natural movement, the bane of most woodworkers' lives, that I use to advantage in my work. The shrinkage and consequent distortion of the wood is not a random occurrence, but can be predicted after studying the form of the grain. In simple terms, the wood never shrinks along the length of the grain, but the annual rings always shrink in circumference. Uniform growth rings and straight grain will result in an even distortion, wild grain produces wild distortion. How the wood is aligned on the lathe initially, will determine whether the distortion of form produced will be symmetrical or asymmetrical. it will also determine whether or not the marriage of form and distortion works aesthetically. The unpredictability is not in how the wood will distort, but in how far it will move.

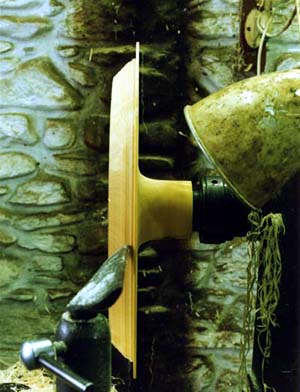

The block of wood is initially cut from the butt and roughly shaped with a chainsaw. It is then affixed to the lathe and shaped by cutting the spinning block with hand held gouges. The outside of the piece is shaped first and when the form is "right", the inside is hollowed out to achieve a uniform wall thickness. Incidentally, the terms inside and outside surfaces are rather arbitrary when referring to my more recent work as the inside often ends up on the outside and vice versa! As the shape of many of the pieces negates the use of callipers to check the thickness of the wall, this is usually gauged by shining a light through the wood which is translucent when full of sap but opaque when dry. The uniformity of the wall thickness is important as the wood needs to be flexible enough to withstand the stresses created as it dries and shrinks.

The shaping of a piece, which may take as long as 12 hours, has to be completed in one "sitting", as the timber will begin to distort if left overnight. This rapid distortion is not due to drying, but to the relief of stresses, which developed as the timber grew, by the removal of large quantities of the surrounding wood. The final cuts are crucial and, when making a large or complicated form, occur when one's concentration and energy levels are almost exhausted. A slight slip, or momentary loss of concentration, at this stage can so easily result in the complete ruination of the piece.

Once the shaping is completed, the piece is left to dry and distort, a process which takes about 4 to 6 weeks. Once dry, each piece is sanded, mostly by hand, as there is no other satisfactory way of sanding complex compound curves. At this stage I become extremely critical of the work and only sand the aesthetically "right" pieces. When I am left with, what I consider to be, boring pieces to sand, I start turning more and throw the rest away. This can lead to a wastage of up to 50% of the pieces turned, but I cannot imagine producing work that I find unexciting. The sanding process is sheer hard grind, an ordeal which can take up to three times as long as the initial shaping of the piece. However, there is no short cut to achieving a faultless finish. It is during this process that a piece "comes to life" and becomes an object in its own right, unconnected to me. Once the piece has been sanded it is then sprayed with water to raise the grain. When dry it is lightly sanded again. Four or five coats of oil are then applied over a 4 day period and when dry this is then rubbed down almost to the bare wood. Finally the piece is given a wax polish.

The green colouring of some of my work is achieved by the application of a solution of ferrous sulphate to the finished piece prior to oiling. The iron in the solution reacts with the tannic acid in the wood and imparts the colour to the fibres. The colour achieved varies with different species and sometimes from tree to tree within the same species, but it is always in the blue/green, green/brown spectrum.

The process of design is usually a development of previous forms, hence the strong individual feel to my work. The forms I produce have all developed from one original form and its negative; this was a simple hemispherical vessel, the plain trumpet form being the negative shape. Although the process of shaping the work is akin to that of the carver, i.e. reducing a block of solid material, but one which happens to be spinning; the end result often has a strong affinity with ceramics. For the past couple of years, the vessel forms appear to be recessive, being found only in the rocking pots. The trumpet form however has developed into the tubular forms, the latest of which I consider to be amongst the finest pieces I have yet made. And, of course, the hollow rim vessel form has lost its centre to become the annular forms, with which I am immensely pleased.